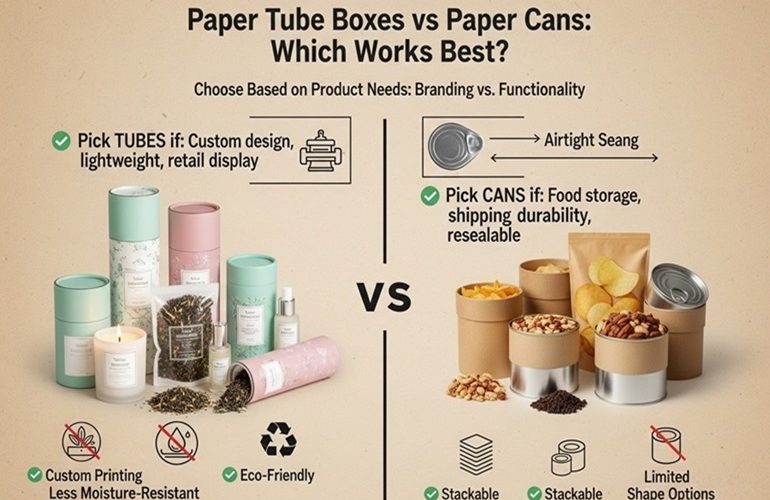

Many businesses struggle with choosing the right cylindrical packaging. Paper tube boxes and paper cans look similar but serve different purposes. This guide explains the main differences between these packaging options. You will learn which one suits your product best.

What Are Paper Tube Boxes and Paper Cans?

Paper tube boxes are lightweight cylindrical containers. They mainly serve as outer packaging for branding purposes. These boxes often have open ends or telescopic designs.

Paper cans are stronger cylindrical containers. They act as primary packaging that directly holds products. These cans feature sealed structures with protective barriers.

Key Structural and Functional Differences

The table below shows the main differences between these packaging types:

| Feature | Paper Tube Boxes | Paper Cans Packaging |

|---|---|---|

| Structure | Open-ended or telescopic design | Fully sealed cylindrical container |

| Wall Strength | Lighter walls, basic rigidity | Thicker walls for better protection |

| Primary Use | Outer branded packaging | Primary product container |

| Bottom Closure | Glued shut or telescopic fit | Metal, plastic, or foil sealing |

| Top Closure | Paper or paperboard cap | Resealable, tamper-proof options |

| Barrier Protection | Minimal protection | Foil or plastic liners included |

| Product Contact | Rarely touches products directly | Designed for direct product storage |

Industries That Use Paper Cans

Paper cans work well in many industries. Businesses choose them when products need protection and attractive branding.

Food and Beverage Industry

Food companies use paper cans for many products:

- Snack manufacturers pack nuts and chips in paper cans

- Beverage companies use them for powdered drinks and coffee

- Spice producers store seasonings in sealed paper cans

- Dairy companies package powdered milk in protective cans

Health and Wellness Sector

Health companies rely on paper cans for supplement packaging:

- Supplement brands store capsules and tablets safely

- Fitness companies package protein powders securely

- Herbal medicine producers use them for powdered remedies

Beauty and Personal Care

Beauty brands choose paper cans for various products:

- Skincare companies package face masks and scrubs

- Bath product makers use them for bath salts

- Cosmetic brands store creams in protective containers

Other Industries

Many other sectors benefit from paper can packaging:

- Candle makers create attractive packaging for their products

- Pet food companies package treats and supplements

- Gift companies use them for promotional and festive items

- Retail stores package socks, toys, and eco-products

Insert Options for Paper Cans

Paper cans can include various inserts to protect products better. These inserts secure items and prevent damage during shipping.

| Insert Type | Common Applications |

|---|---|

| Cardboard Disc | Holds products in place, creates layers |

| Foam Insert | Protects delicate items like glass containers |

| Plastic Tray | Provides stability for cosmetics and supplements |

| Blister Pack Insert | Secures pills and small accessories |

| Divider Inserts | Separates multiple products in gift sets |

| Paper Pulp Mold | Offers eco-friendly shock absorption |

| Aluminum Foil Liners | Creates barrier protection for food products |

Lid Options for Paper Cans

Paper cans offer flexible lid choices. Different industries need different closure types for their specific requirements.

Top Lid Varieties

Paper can manufacturers provide several top lid options:

| Lid Type | Key Features and Uses |

|---|---|

| Metal Lid (Slip-On) | Creates premium appearance, provides good seal |

| Plastic Lid (Snap-On) | Offers resealable convenience for snacks |

| Paperboard Lid | Provides fully recyclable, eco-friendly option |

| Foil Seal Lid | Ensures tamper-evident security for food |

| Embossed Metal Lid | Adds luxury appeal for premium products |

| Easy Peel-Off Foil | Maintains hygiene standards in packaging |

Bottom Sealing Options

Bottom closures also vary based on product needs:

| Bottom Type | Best Applications |

|---|---|

| Metal Base | Adds weight and durability to containers |

| Paperboard Base | Provides lightweight, eco-friendly solution |

| Aluminum Foil Seal | Seals in freshness for teas and spices |

| Plastic Base Insert | Works well for refillable packaging systems |

Which Packaging Should You Choose?

Your product type determines the best packaging choice. Consider these factors when making your decision:

| Use Case | Recommended Choice |

|---|---|

| Fancy gift packaging | Paper Tube Boxes |

| Food-grade product storage | Paper Cans Packaging |

| Products needing protection and branding | Paper Cans |

| Light outer packaging only | Paper Tubes |

Benefits of Each Packaging Type

Paper Tube Boxes Advantages

Paper tube boxes work well for specific applications:

- Companies save money with lightweight construction

- Brands create attractive outer packaging easily

- Businesses reduce shipping costs with lighter materials

- Manufacturers customize designs for marketing purposes

Paper Cans Advantages

Paper cans offer superior protection and functionality:

- Products stay fresh with barrier protection

- Businesses ensure food safety with proper sealing

- Companies create premium brand experience

- Manufacturers provide tamper-evident security

Making the Right Choice

Consider these questions when choosing packaging:

- Does your product need direct container contact?

- Do you require barrier protection for freshness?

- Is your packaging primarily for branding or protection?

- Do you need resealable or tamper-evident features?

Products requiring direct storage need paper cans. Items needing only outer packaging work well with paper tube boxes.

Conclusion

Paper tube boxes and paper cans serve different packaging needs. Paper tube boxes work best for lightweight outer packaging and gift applications. Paper cans excel at protecting products that need direct container storage.

Food companies, supplement manufacturers, and beauty brands typically choose paper cans. Gift companies and businesses needing simple outer packaging often select paper tube boxes.

Your product requirements determine the best choice. Consider protection needs. Direct contact requirements, and branding goals when making your decision. Both options offer unique advantages for different business applications.

2 Comments

I’ve always been curious about the durability of paper packaging in more demanding industries like electronics. The idea that paper cans could potentially be more durable than tube boxes makes a lot of sense for such products. Do these types of packaging hold up well to moisture and temperature changes?

That’s a great question. Paper packaging, particularly for electronics, is designed to be surprisingly durable. We use special coatings and laminates to protect against moisture and temperature fluctuations. Which makes it a viable and often more sustainable alternative to traditional plastic or foam packaging.